Ingxoxo eneenkcukacha kuYilo kunye noPhando lweNkqubo yeNdibano yeValve eyiNgqondo

Intshayelelo

Ekubeni inkqubo yendibano ngumgca wemveliso kunye neyunithi yokuvelisa ehlakaniphile, kunye nokuphuculwa okuqhubekayo kobuchwephesha bokulawula obukrelekrele kunye nokucubungula okucokisekileyo, iqondo layo lokuzenzekelayo liyaqhubeka likhula.Gqiba.Ivalve engundoqo yolawulo lwenkqubo yokuhlanganisa ekrelekrele eyilwe kweli phepha iqonda i-automation engundoqo yokukhethwa kwezinto kunye nokutshixa ivalve, kunye neemveliso ezineziphene zidityaniswe nenkqubo yobhaqo ukuze kuhlelwe indibano.Yamkela i-PLC kunye nojongano lomatshini woluntu ukwenza inkqubo, kunye nesakhiwo somatshini siyilwe kwaye sinengqiqo.Ukugqitywa koyilo lwale nkqubo kuphucula kakhulu ukusebenza kakuhle kwemvelisoundoqo wevalveifakwe kwivalve, kwaye ibonelela ngomzekelo wokwakhiwa kolu hlobo lwenkqubo.

Ngokunyuka ngokukhawuleza kwenani leiindawo zevalvu, umthamo womoya uyaqhubeka nokunyuka, okuyinqanaba apho imoto yokuqhuba ngokuzenzekelayo isemnyango, kwaye ingundoqo yemoto emnyango iyancipha ngakumbi, kwaye umnyango awukwazi ukuvalelwa.Umntu unokuqonda umsebenzi wokubona obukrelekrele Imodyuli ekrelekrele inokuqonda ingxaki ekrelekrele kwimodyuli ekrelekrele [1].Ukuphucula ukusebenza kakuhle kwemveliso kunye nesantya esihle.

1. Uhlalutyo lobunzima be-valve core kunye nenkqubo yokuhlanganisana kwayo

Kolu phononongo, emva kokufunxa amava oyilo lwezinye iinkqubo zokudityaniswa okuzenzekelayo, inkqubo yendibano ekhoyo yesemi-automatic yahlalutywa, kwaye inxalenye yomatshini yenkqubo yayiyilwe ngokupheleleyo ngokusekelwe ekufaniseni inkqubo yokuhlanganisa isiseko sevalve.Kwisicwangciso soyilo lwenkqubo, sizama ukwenza ukuba ukusetyenzwa kwamalungu oomatshini kube lula, ukunciphisa iindleko, ukwenza ukudityaniswa kwamalungu kube lula kwaye kube lula, kwaye senze inkqubo ibe nenqanaba elithile lokuvuleleka kunye nokwandiswa, ukuze kuphuculwe ukuthembeka. kunye nokusebenza kakuhle kwenkqubo., kwaye ubeke isiseko esihle sokuphucula ukusebenza kweendleko zenkqubo .

Inkqubo yokudityaniswa kwe-valve coreubukhulu becala yahlulahlulwe yaziinxalenye ezintathu ngokwendlela yoyilo lwesakhiwo soomatshini, ezizezi: iinxalenye ezimbini zendibano kwikona ephezulu ngasekhohlo yebhentshi yokusebenzela, iinxalenye ezintathu zendibano kwikona esezantsi ekhohlo kunye neendibano ezisixhenxe kwicala lasekunene lendawo yokusebenza.Ubunzima bobugcisa bendibano yamacandelo amabini buxhomekeke kwindlela yokuqinisekisa ukuma kwesetyhula kwindandatho yokutywina.Ngethuba lenkqubo yokusika, iya kufakwa phantsi kwe-axial extrusion force ye-blade, ngoko kulula ukukhubaza.Okwesibini, ngexesha lenkqubo yokuhlanganisana, xa i-cored rod ifunyenwe kwi-tooling tooling component, kuyimfuneko ukuqonda ukukhangela kunye nokudibanisa phakathi kwamacandelo ahlukeneyo engundoqo yomnyango ngokusebenzisa i-vibration.Ngoko ke, icandelo ngalinye liwela kwindawo ehambelanayo ukuze libe likhonkco lendibano.Ubunzima benkqubo bulele.Ezi ngxaki zingentla zizizathu eziphambili zokunyuka kwezinga lemveliso ephosakeleyo kwindibano ye-valve core kule nqanaba.Ngokusekelwe koku, eli phepha lilungiselela inkqubo yokudibanisa i-valve core, kwaye yongeza inkqubo yokuhlola umgangatho wokuphucula izinga lokufaneleka kwe-valve core assembly.

2. Uyilo lwenkqubo ekrelekrele yondoqo wevalvu emlonyeni wevalvu

-

2.1 Uyilo lwesikimu sendibano yevalve engundoqo

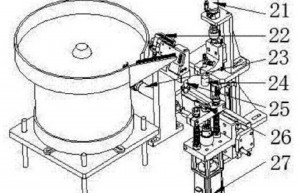

I-interface yokusebenza kunye ne-PLC yenze inxalenye yokulawula ingqiqo, kwaye inkqubo yokufumanisa kunye ne-PLC ineendlela ezimbini zokuhamba kolwazi ukuqokelela idatha yesimo senkqubo yendibano kunye nokukhupha isignali yokulawula.Njengenxalenye yesigqeba, inkqubo yokuqhuba ilawulwa ngokuthe ngqo yi-PLC inxalenye yemveliso.Ngaphandle kwenkqubo yokutya, efuna uncedo lwezandla, ezinye iinkqubo kule nkqubo ziye zaqonda indibano ekrelekrele.Ukusebenzisana okuhle komntu-kwikhompyuter kufezekiswa ngesikrini sokuchukumisa.Ukuqwalasela ukulungelelaniswa kokusebenza kuyilo lomatshini, ibhokisi yokubeka ingundoqo yomnyango isecaleni kwesikrini sokuchukumisa.Indlela yokubona, undoqo womnyango wokuvuthela icandelo elivuthela phezulu, icandelo lokubona ubude bevalve kunye nesixhobo sokuvala ngokulandelelanayo zicwangciswe ngokujikeleze icandelo lesixhobo se-turntable, ukuqonda uyilo lwemveliso yomgca wendibano yendibano engundoqo yocango.Inkqubo yokufumanisa ngokuyinhloko igqibezela ukufumanisa intonga engundoqo, ukukhangela ukuphakama kofakelo, ukuhlolwa komgangatho, njl., Engaqapheli nje ukuzenzekelayo kokukhethwa kwezinto kunye ne-valve core lock, kodwa iqinisekisa ukuzinza kunye nokusebenza okuphezulu kwenkqubo yokuhlanganisa.Ubume beyunithi nganye yenkqubo buboniswe kulo mfanekiso ulandelayo.

Njengoko kuboniswe kwi-Figure 1, i-turntable iyikhonkco ephakathi kwayo yonke inkqubo yokuhamba, kwaye indibano ye-valve core igqitywe ngokuqhutywa kwe-turntable.Xa indlela yesibini yokufumanisa ibona icandelo eliza kuhlanganiswa, lithumela isignali kwinkqubo yokulawula, kwaye inkqubo yokulawula ilungelelanisa umsebenzi weyunithi nganye yenkqubo.Okokuqala, idiski engcangcazelayo ishukumisa undoqo wocango kwaye iyitshixe kumlomo wevalve yokungena.Indlela yokuqala yokufumanisa iya kukhusela ngokuthe ngqo i-valve cores engazange ifakwe ngempumelelo njengezinto ezimbi.Icandelo lesi-6 lifumanisa ukuba i-ventilation ye-valve core ifanelekile, kwaye icandelo lesi-7 lifumanisa ukuba ukuphakama kofakelo lwe-valve core kuhambelana nomgangatho.Kuphela ziimveliso ezifanelekileyo kula manyathelo mathathu angasentla ziya kuthathwa kwibhokisi yemveliso elungileyo, kungenjalo ziya kuphathwa njengemveliso eneziphene.

2.2 Uyilo lwamalungu aphambili enkqubo yokuhlanganisa ivalvu engundoqo

Njengenkqubo ephambili yokufakela i-valve core kwivalve, ukutshixa i-valve core kuneemfuno eziphezulu kakhulu malunga nokuchaneka kwendawo yokunyakaza ye-valve core, ngoko ke idinga ukulungelelaniswa kweendlela ze-longitudinal kunye ne-lateral ukuze igqibe.Kuyilo lwale nxalenye, ibolile ibe yinto enye, isenzo sokukhupha i-valve core, isenzo sokutshixa i-lever yokutshixa kunye nesenzo sokulayisha i-valve core kwi-valve nozzle.Ubume bayo bomatshini buboniswe kwi-Figure 2.

Njengoko kunokubonwa kwi-Figure 2, i-mechanical structure ye-valve core assembly yahlulwe yangamacandelo amathathu.La malungu mathathu asebenza ngolungelelwaniso ngaphandle kokuchaphazela omnye nomnye.Xa isenzo esizimeleyo sigqityiwe, isilinda sityhala indlela yokufudukela kwindawo yokuhlanganisa elandelayo.Ukuze kuqinisekiswe ukuchaneka kwendawo ehambayo, uyilo olubanzi lolawulo lombane kunye nomda womatshini wamkelwa ukulawula impazamo ngaphakathi kwe-1.4mm.Umbindi wevalve kunye nombindi womlomo wevalve zi-coaxial, ukuze i-servo motor ityhale undoqo wevalve kumlomo wevalve kakuhle, kungenjalo iya kubangela umonakalo kwiindawo.

Ukuma kwesakhiwo soomatshini okanye ii-pulses ezingaqhelekanga zemiqondiso yombane kunokubangela ukuphambuka okuncinci kumsebenzi wendibano.Ngenxa yoko, emva kokuba i-valve core ihlanganiswe, ukusebenza kwe-ventilation ayikho kumgangatho, kwaye ukuphakama kwendibano akufanelekile, okukhokelela ekungaphumeleli kwemveliso.Lo mba uqwalaselwe ngokupheleleyo kuyilo lwenkqubo, ukufumanisa ukuvuthuza komoya kunye nokuchongwa kobude kusetyenziswa ukuhlenga iimveliso ezimbi.

2.3 Uyilo lwenkqubo yokulawula ukudityaniswa kwevalvu engundoqo

Inkqubo yolawulo kolu yilo ikakhulu ibandakanya ulawulo lwengqiqo lwePLC, inkqubo ye-servo motor drive, inkqubo yokufumanisa kunye nojongano lomatshini we-HMI.Inkqubo ye-servo drive ikakhulu iqulunqwe yi-servo motor, i-reducer, njl., Eqhuba iindawo zomatshini ukuhamba emva kokufumana umqondiso.Inkqubo ye-servo inokuqonda indawo echanekileyo kunye nohlengahlengiso lwesantya phantsi kolawulo lwe-PLC.Inkqubo yokufumanisa ibandakanya i-photoelectric sensors, i-sensors zokukhanya, i-laser sensors, njl., eqaphela ngokukodwa imisebenzi yokujonga indawo, ukubonwa kweengxenye kunye nokuchongwa, kunye nokuhambelana nokulandelelana kwenkqubo.Ujongano lomatshini womntu we-HIM wamkela imodyuli yenkqubo yegraphical, enokuqonda ukusebenzisana okuhle komatshini womntu.Umsebenzisi unokulawula ngokuthe ngqo inkqubo ngokusebenzisa i-interface yokusebenza, kwaye inkqubo yendibano kunye neeparitha nazo zinokuboniswa ngokuthe ngqo kwi-interface.

Inkqubo inokukhetha imowudi yokuhlanganisa ngesandla kunye nemowudi yokuhlanganisa ngokuzenzekelayo ngokusebenzisa ujongano lokusebenza.Kwimo ezenzekelayo, inkqubo ihlanganisana ngokuzenzekelayo ngokwenkqubo yendibano.Kwimowudi yokusebenza ngesandla, inkqubo isebenza kwinqanaba elinye, kwaye isenzo ngasinye sokusebenza asiyi kuqhuba ngokuqhubekayo.Ukuphunyezwa kwenkqubo yenkqubo iqala kwi-sub-network ye-rotation ye-turntable, i-PLC ikhupha ulawulo lwesignali yokulawula, kunye ne-servo motor iqhuba ukulayishwa kunye nokujikeleza kwediski.Xa i-turntable ithwala i-valve core kwindawo yenkqubo ye-teknoloji ehambelanayo, i-subroutine yenkqubo ye-teknoloji iqhuba, kwaye icandelo lokuphumeza lenza isenzo esihambelanayo ngokuhambelana nomqondiso wokulawula.

3. Isiphelo

Ukuhamba kwenkqubo yofakelo olungundoqo lwevalvu luvuliweivalveayinzima, kodwa iimfuno zokuphucula inkqubo ziphezulu kakhulu.Ngoko ke, indibano yezandla kunye ne-semi-automatic assembly isetyenziswa kakhulu kwimveliso yefektri, kwaye ukusebenza kwabo kunye nomgangatho awuzinzile.Kweli phepha, inkqubo yokudibanisa ekrelekrele yesiseko sevalve ebekwe kwivalvu iyilwe, eqonda ukuzenzekelayo kokukhethwa kwezinto kunye nokutshixa undoqo wevalve, kwaye ichonge ukusebenza komoya kunye nokuphakama kofakelo lwendibano engundoqo yevalve ngenkqubo yobhaqo, kunye iziphumo zobhaqo zilayishwa ngokuzenzekelayo kwisixokelelwano solawulo ukuqaphela ukuhlelwa ngokuzenzekelayo kweemveliso ezineziphene.Ukusebenza kakuhle kunye nokuzinza kwemveliso ye-valve core efakwe kwi-valve nozzle iyaphuculwa.

Bhala umyalezo wakho apha kwaye uwuthumele kuthi