1. Uvavanyo lwethiyori kunye nohlalutyo

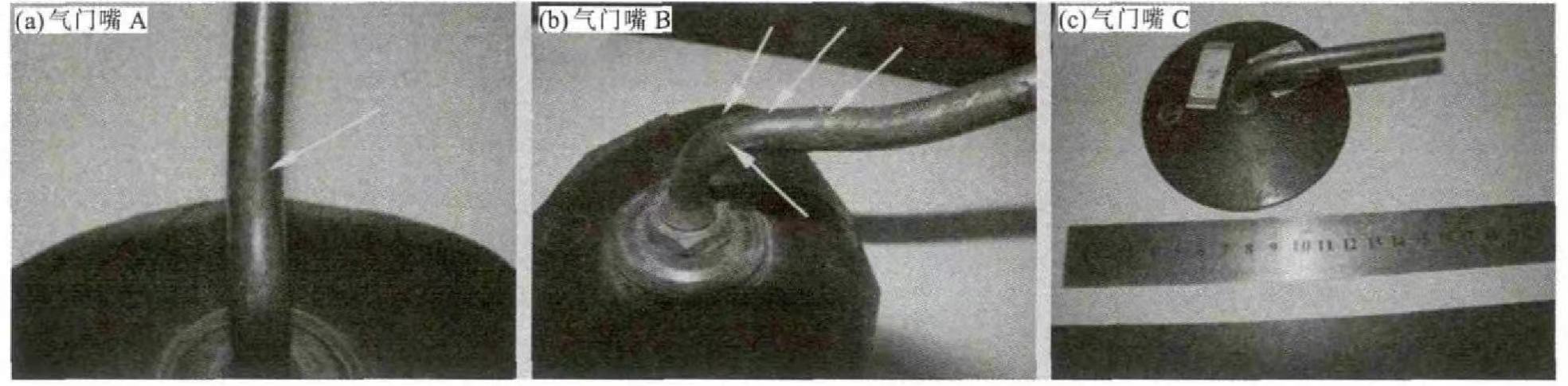

Kwesi-3iivalve zamatayaraiisampulu ezibonelelwe yinkampani, i-2 ziivalvu, kwaye i-1 yivalve engekasetyenziswa okwangoku. Ku-A no-B, ivalve engasetyenziswanga imakishwa njengengwevu. Umzobo obanzi 1. Umphandle wevalve A awunzulwanga, umphandle wevalve B ngumphezulu, umphandle wevalve C ngumphezulu, kwaye umphandle wevalve C ngumphezulu. Iivalvu A kunye no-B zigqunywe ngeemveliso zomhlwa. Ivalve A kunye no-B ziqhekeziwe kwiindawo zokugoba, indawo engaphandle yokugoba ikunye nevalve, ivalve ring umlomo B iqhekeziwe ukuya ekupheleni, kwaye utolo olumhlophe phakathi kweendawo eziqhekekileyo kumphezulu wevalve A uphawulwe. Ukusuka apha ngasentla, iintanda zikhona kuyo yonke indawo, iintanda zezona zikhulu, kwaye iintanda zikhona kuyo yonke indawo.

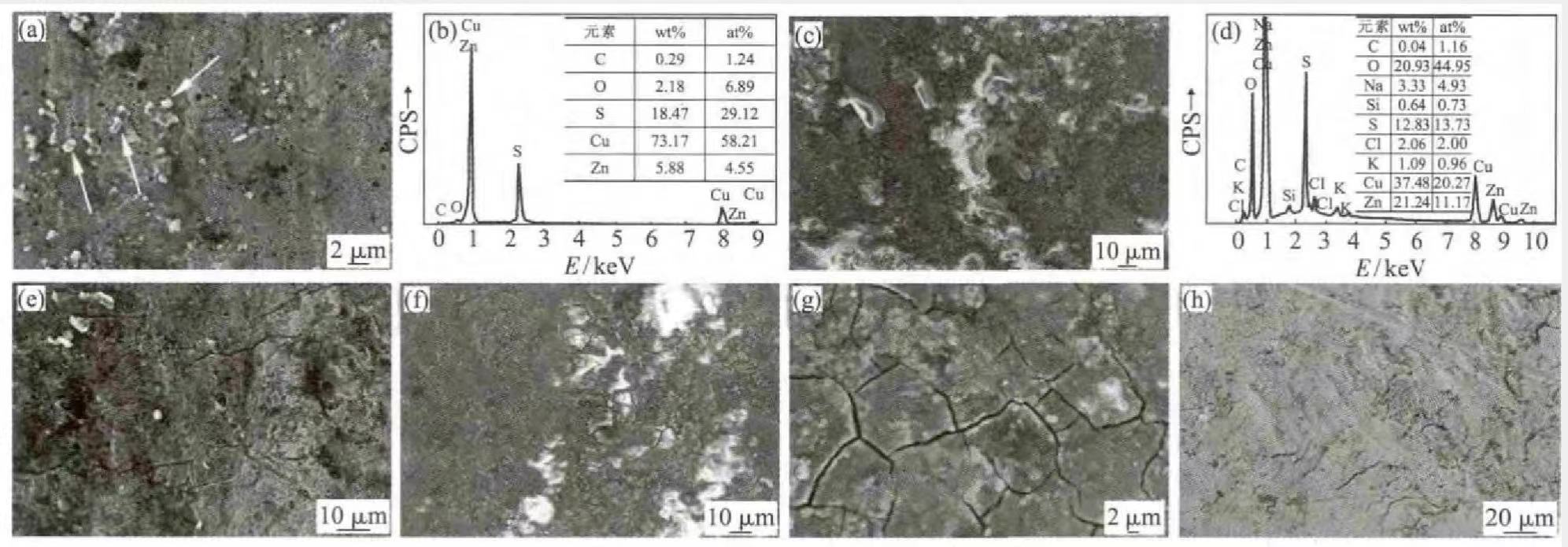

Icandelo leivalve yetayaraIisampuli ze-A, B, kunye ne-C zanqunyulwa kwi-bend, kwaye i-morphology ye-surface yabonwa nge-ZEISS-SUPRA55 yokuskena i-electron microscope, kwaye ukubunjwa kwendawo encinci kuhlalutywe nge-EDS. Umzobo 2 (a) ubonisa i-microstructure yendawo yevalve B. Ingabonwa ukuba kukho iinqununu ezininzi ezimhlophe kunye ezikhanyayo phezu komhlaba (ezibonakaliswe ngeentolo ezimhlophe kumfanekiso), kwaye uhlalutyo lwe-EDS lwamaqhekeza amhlophe lunomxholo ophezulu we-S. Iziphumo zohlalutyo lwe-energy spectrum ezimhlophe ziboniswa kuMfanekiso 2 (b).

I-Figure 2 (c) kunye (e) yi-microstructures yomhlaba we-valve B. Inokubonwa kwi-Figure 2 (c) ukuba umphezulu uphantse ugutyungelwe yimveliso ye-corrosion, kunye ne-corrosion elements yemveliso ye-corrosion nge-energy spectrum analysis ikakhulukazi ibandakanya i-S, i-Cl kunye ne-O, umxholo we-S kwizikhundla zomntu ngamnye uphezulu, kunye neziphumo zohlalutyo lwe-2 (i-drug spectrum). Inokubonwa kwi-Figure 2 (e) ukuba kukho ii-micro-cracks ecaleni kweringi yevalve kumphezulu wevalve A. Amanani 2 (f) kunye (g) yi-micro-morphologies yomphezulu wevalve C, umphezulu nawo ugutyungelwe ngokupheleleyo yimveliso yokubola, kunye nezinto ezibolayo zikwabandakanya i-S, Cl kunye ne-O, efana noMzobo 2 (e). Isizathu sokuqhekeka sinokuba yi-stress corrosion cracking (SCC) ukusuka kuhlalutyo lwemveliso ye-corrosion kwi-valve surface. Umzobo we-2 (h) kwakhona i-microstructure ye-valve ye-valve C. Iyakwazi ukubonakala ukuba umphezulu ucocekile, kwaye i-chemical composition of the surface ehlalutywe yi-EDS ifana ne-alloy yobhedu, ebonisa ukuba i-valve ayinayo i-corrod. Ngokuthelekisa i-microscopic morphology kunye nokwakhiwa kweekhemikhali zeendawo ezintathu zevalve, kuboniswa ukuba kukho imidiya ephazamisayo efana ne-S, O kunye ne-Cl kwindawo engqongileyo.

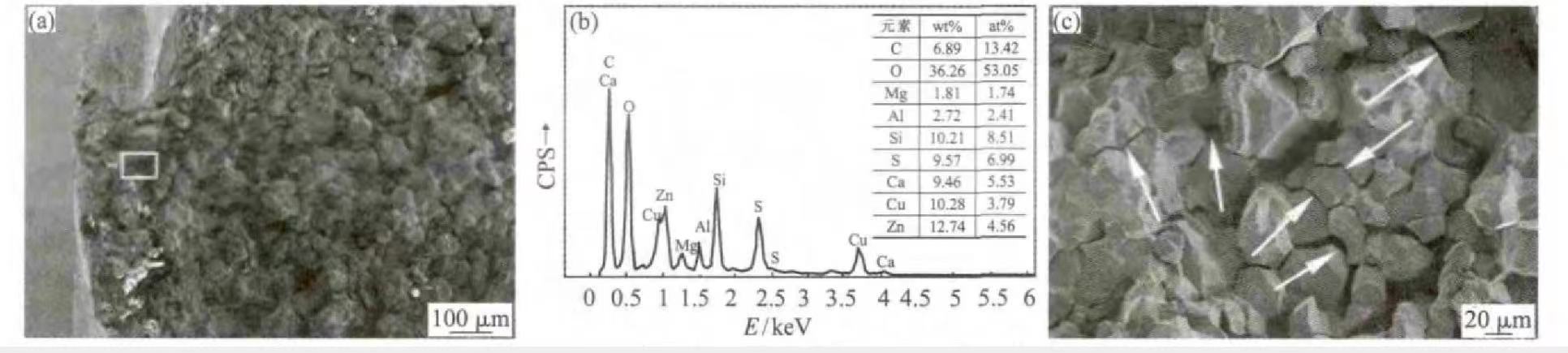

Ukuqhekeka kwevalve B kwavulwa ngovavanyo lokugoba, kwaye kwafunyaniswa ukuba ukuqhekeka akuzange kungene kulo lonke icandelo elinqamlezayo levalve, liqhekeke kwicala le-backbend, kwaye alizange liqhekeke kwicala elijongene ne-backbend yevalve. Ukuhlolwa okubonakalayo kokuqhekeka kubonisa ukuba umbala we-fracture umnyama, obonisa ukuba i-fracture iye yatshitshiswa, kwaye ezinye iindawo zokuqhekeka zinombala omnyama, obonisa ukuba ukubola kubi kakhulu kula macandelo. Ukwaphuka kwevalve B kuye kwaqatshelwa phantsi kwe-electron yokuskena imakroskopu, njengoko kubonisiwe kuMfanekiso 3. Umzobo 3 (a) ubonisa inkangeleko enkulu yokwaphuka kwevalve B. Ingabonwa ukuba i-fracture yangaphandle kufuphi ne-valve igutyungelwe yimveliso ye-corrosion, iphinda ibonise ubukho beendaba ezinobungozi kwindawo engqongileyo. Ngokutsho kohlalutyo lwe-spectrum yamandla, iikhemikhali zemveliso ye-corrosion ziyi-S, Cl kunye ne-O, kunye neziqulatho ze-S kunye ne-O ziphezulu, njengoko kuboniswe kwi-Fig. 3 (b). Ukujonga umphezulu wokwaphuka, kufunyaniswe ukuba ipateni yokukhula kokuqhekeka isecaleni kohlobo lwekristale. Inani elikhulu leentanda zesibini nazo zingabonwa ngokuqwalasela ukuphuka kwi-magnifications ephezulu, njengoko kubonisiwe kuMfanekiso 3 (c). Iintanda zesibini ziphawulwe ngeentolo ezimhlophe kumfanekiso. Iimveliso ze-Corrosion kunye neepateni zokukhula kwe-crack kwindawo yokuphuka kwakhona zibonisa iimpawu zoxinzelelo lwe-corrosion cracking.

Ukuqhekeka kwevalve A akukavulwa, susa icandelo levalve (kubandakanywa nendawo eqhekekileyo), ugaye kwaye upholise icandelo le-axial yevalve, kwaye usebenzise i-Fe Cl3 (5 g) + HCl (50 mL) + C2H5OH (100 mL) isisombululo sabhalwa, kwaye isakhiwo se-metallographic kunye ne-crack growth morphology yabonwa nge-Zeispservermic morphology. Umzobo 4 (a) ubonisa i-metallographic structure yevalve, eyi-α+β ye-dual-phase structure, kunye ne-β ilungile kwaye i-granular kwaye isasazwe kwi-matrix yesigaba se-α. Iipateni zokusasazwa kwee-crack kwii-cracks ezijikelezayo ziboniswa kuMfanekiso 4 (a), (b). Kuba imiphezulu yokuqhekeka izaliswe ziimveliso zomhlwa, umsantsa phakathi kwemiphezulu emibini yokuqhekeka ubanzi, kwaye kunzima ukwahlula iipateni zokusasaza kweentanda. i-bifurcation phenomenon. Iintanda ezininzi zesibini (eziphawulwe ngeentolo ezimhlophe emfanekisweni) nazo zabonwa kolu qhekeko oluphambili, jonga umzobo 4 (c), kwaye ezi zintlukwano zesibini zasasazwa ecaleni kwengqolowa. Isampulu yevalve echongiweyo yabonwa yi-SEM, kwaye kwafunyaniswa ukuba kukho iintanda ezininzi ezincinci kwezinye izikhundla ezihambelana nokuqhekeka okuphambili. Ezi crack ezincinci zisuka phezulu kwaye zanda ukuya ngaphakathi kwivalve. Iintanda zazicandeke kabini zaza zanda ecaleni kweenkozo, jonga uMfanekiso 4 (c), (d). Ubume bemeko kunye noxinzelelo lwemeko yezi microcracks ziphantse zifane nezo ze-crack eziphambili, ngoko kunokucingelwa ukuba ifom yokusabalalisa i-crack engundoqo nayo i-intergranular, ephinda iqinisekiswe ngokubonwa kwe-valve ye-valve B. I-bifurcation phenomenon ye-crack kwakhona ibonisa iimpawu zoxinzelelo lwe-corrosion cracking yevalve.

2. Uhlalutyo kunye neNgxoxo

Ukushwankathela, kunokuchazwa ukuba umonakalo wevalve ubangelwa kukuqhekeka kwe-corrosion yoxinzelelo olubangelwa yi-SO2. Uxinzelelo lwe-corrosion cracking ngokubanzi lufuna ukuhlangabezana neemeko ezintathu: (1) izinto ezithintekayo kuxinzelelo lwe-corrosion; (2) i-corrosive medium sensitive to copper alloys; (3) iimeko ezithile zoxinzelelo.

Ngokuqhelekileyo kukholelwa ukuba iintsimbi ezicocekileyo azikhathazwa kukuhlwa koxinzelelo, kwaye zonke i-alloys zisengozini yoxinzelelo lwe-corrosion ukuya kumaqondo ahlukeneyo. Kwizinto zobhedu, ngokuqhelekileyo kukholelwa ukuba isakhiwo sesigaba sesibini sinoxinzelelo oluphezulu lwe-corrosion susceptibility kunesakhiwo sesigaba esisodwa. Kuye kwaxelwa kwiincwadi ukuba xa umxholo we-Zn kwizinto zobhedu zidlula i-20%, unoxinzelelo oluphezulu lwe-corrosion susceptibility, kwaye iphakamileyo umxholo we-Zn, uphezulu ukuxhatshazwa kwe-corrosion susceptibility. Isakhiwo se-metallographic sombhobho wegesi kule meko yi-alloy ye-α + β ye-double-phase, kwaye umxholo we-Zn umalunga ne-35%, ugqithise kakhulu i-20%, ngoko unoxinzelelo oluphezulu lwe-corrosion sensitivity kwaye ihlangabezana neemeko eziphathekayo ezifunekayo kwi-stress corrosion cracking.

Kwimathiriyeli yobhedu, ukuba i-annealing yokunciphisa uxinzelelo ayenziwa emva kokuguqulwa kokusebenza okubandayo, i-corrosion yoxinzelelo iya kwenzeka phantsi kweemeko ezifanelekileyo zoxinzelelo kunye neendawo ezinobungozi. Uxinzelelo olubangela uxinzelelo lwe-corrosion cracking ngokubanzi luxinzelelo lwe-tensile yendawo, enokuthi isetyenziswe uxinzelelo okanye uxinzelelo olushiyekileyo. Emva kokuba itayara lelori livuthelwe umoya, uxinzelelo luya kuveliswa ecaleni kwe-axial ye-nozzle yomoya ngenxa yoxinzelelo oluphezulu kwitayara, okuya kubangela iintanda ezijikelezayo kumlomo womoya. Uxinzelelo lwe-tensile olubangelwa uxinzelelo lwangaphakathi lwevili lunokubalwa ngokulula ngokwe-σ=p R/2t (apho i-p ixinzelelo lwangaphakathi lwesondo, i-R yi-diameter yangaphakathi yevalve, kunye ne-t ubukhulu bodonga lwevalve). Nangona kunjalo, ngokubanzi, ukunyanzeliswa koxinzelelo olwenziwa luxinzelelo lwangaphakathi lwesondo alukhulu kakhulu, kwaye umphumo woxinzelelo olushiyekileyo kufuneka uqwalaselwe. Izikhundla eziqhekekileyo zemibhobho yerhasi zonke zikwi-backbend, kwaye kuyacaca ukuba i-deformation eseleyo kwi-backbend inkulu, kwaye kukho uxinzelelo olushiyekileyo apho. Enyanisweni, kwizinto ezininzi ezisebenzayo ze-alloy copper, i-corrosion cracking yoxinzelelo ayifane ibangelwe luxinzelelo loyilo, kwaye uninzi lwazo lubangelwa luxinzelelo olushiyekileyo olungabonakali kwaye lungahoywa. Kule meko, kwi-back back ye-valve, isalathiso soxinzelelo lwe-tensile oluveliswa kuxinzelelo lwangaphakathi lwesondo luhambelana nolwalathiso loxinzelelo olushiyekileyo, kwaye ukugqwesa kwezi zixinzelelo zimbini kunika imeko yoxinzelelo lwe-SCC.

3. Isiphelo kunye neeNgcebiso

Isiphelo:

Ukuqhekeka kweivalve yetayaraibangelwa ikakhulu luxinzelelo lwe-corrosion cracking ebangelwa yi-SO2.

Ingcebiso

(1) Landela umthombo wendlela eyingozi kwindalo esingqongileyoivalve yetayara, kwaye uzame ukunqanda ukudibana ngokuthe ngqo nesixhobo esirhangqe esonakalisayo. Ngokomzekelo, umaleko we-anti-corrosion coating ungafakwa kumphezulu wevalve.

(2) Ukuxinezeleka okushiyekileyo kokusebenza okubandayo kunokupheliswa ngeenkqubo ezifanelekileyo, ezifana nokunciphisa uxinzelelo emva kokugoba.

Ixesha lokuposa: Sep-23-2022