1. Ulwazi Lwemvelaphi

Ivili lokuBhabha lokuPhila kabini (i-DMFW) lulungelelwaniso olutsha oluvele kwiimoto ekupheleni kweminyaka yoo-1980, kwaye lunesiphumo esihle kukwahlulwa kokungcangcazela kunye nokunciphisa ukungcangcazela koololiwe bamandla emoto.

Ii-lug nutskukwahlula i-flywheel yokuqala ibe ngamacandelo amabini. Inxalenye enye ihlala kwicala elinye le-injini yokuqala kwaye isebenza njenge-flywheel yokuqala ukuqalisa kunye nokuhambisa i-torque ejikelezayo ye-injini. Le ndawo ibizwa ngokuba yiprimary mass; enye inxalenye ibekwe kwicala lothumelo lomzila wokuqhuba ukuphucula inertia ejikelezayo yothumelo. , le nxalenye ibizwa ngokuba nobunzima besibini. Kukho i-oil cavity ye-annular phakathi kwamacandelo amabini, kunye ne-spring shock absorber ifakwe kwi-cavity, ejongene nokudibanisa iinxalenye ezimbini ze-flywheel, njengoko kuboniswe kuMzobo 1. Ubunzima besibini bunokunyusa umzuzu we-inertia yesitimela sokuqhuba ngaphandle kokunyusa umzuzu we-inertia ye-flywheel, kunye nokunciphisa isantya se-resonance phantsi kwesantya esingenamsebenzi.

Umzi-mveliso we-injini ye-Hexi uvelisa iinjini ezi-5 ezinobunzima obumbini, ezizezi EK/CM/RY/SN/TB. Ii-flywheels ezinobunzima obumbini kwezi njini zi-5 ziqiniswe sisitishi esizenzekelayo (OP2135), kwaye iibholithi zokuqinisa ii-flywheels ezinobunzima obubini ziibholiti zeTorx. Ukuchaneka kokuqina kuyadingeka ukuba kuphakame, kwaye ukuphambuka okuncinci kwi-angle kuya kubangela ukuba ukuqiniswa kungalunganga kwi-shaft. Ngokomyinge, i-15 yeemveliso ezingafanelekanga zavela kwinguqu nganye, okubangelwa inani elikhulu lokulungiswa kunye nokuchaphazela ukusebenza okuqhelekileyo komgca wemveliso.

Okwangoku, isikhululo sokuqinisa i-flywheel esiphindwe kabini samkela indlela yokulawula i-torque kunye ne-engile (35±2)N m+(30~45)° ukujonga itorque yebholiti. Ukongeza, i-torque engatshintshiyo yebholithi ye-flywheel ye-dual-mass inkulu (iimfuno zobugcisa: 65 N · m ~ 86 N·m). Ukuze uhlangabezane neemfuno ze-torque, kufuneka ukuba i-sleeve (njengoko kuboniswe kwi-Figure 3) kunye ne-bolt kufuneka ihambelane ngokuchanekileyo ngexesha lenkqubo yokuqinisa. Ngesi sizathu, eli phepha lenza uphando kunye nohlalutyo olusekwe kwiingxaki zenyani, kwaye liphakamisa izisombululo ezifanelekileyo malunga nendlela yokuphucula umgangatho ofanelekileyo wokuqiniswa kwebholithi ye-flywheel ephindwe kabini.

2. Uphando lokuQiniswa okungafanelekanga kweLug Nuts

Ingxaki "yokuqinisa ngokungalunganga kwiLug Nuts"Ibalelwa kwi-94.63% yenani elipheleleyo labantu abangafanelekanga, eyona nto yayiyingxaki enkulu ebangela ukuba izinga eliphantsi lemfundo le-double-mass flywheel bolt liqiniswe. Emva kokumisela i-crux yengxaki enkulu, sinokumisela iyeza elichanekileyo. Ngokudibanisa nendawo kunye nemeko yokuvelisa, isikhokelo sophando esiphambili siye sacaciswa.

Ngokutsho kwedatha yesimo sophando, idatha ye-459 ye-dual-mass flywheel bolts ukususela ngoJanuwari ukuya ku-Matshi 2021 ayizange igxininiswe kwaye idatha ye-shaft yahlaziywa, njengoko kuboniswe kwiThebhile 1 kunye ne-Figure 6. Emva kohlalutyo, kwafunyaniswa ukuba i-25 ye-flywheel-mass flywheel bolts ayizange iqiniswe kwaye i-shaft data yahlaziywa, njengoko kubonisiwe kwiThebhile 1 kunye ne-Figure 6. Emva kohlalutyo, kwafunyaniswa ukuba i-25 ye-flywheel-mass flywheel bolts ayizange iqiniswe kwaye idatha ye-shaft yahlaziywa, njengoko kuboniswe kwiThebhile 1 kunye nomfanekiso 6. Emva kokuhlalutya, kwafunyaniswa ukuba i-25 ye-double-mass flywheel bolts ihlulekile ukuqiniswa ngenxa yezixhobo zekhamera. ukusebenza okungafanelekanga kwe-pallet, ukulahlekelwa kwemvelaphi yesixhobo, umonakalo kwi-sleeve, njl., ube ne-randomness enkulu. Ngoko ke, i-crux ephambili yale ngxaki ingasombululwa ngokwethiyori ukuya kwinqanaba le-1-25 / 459 = 94.83%.

3. Isisombululo

1. Isisombululo sokunxitywa kwamazinyo ezixhobo zemihlathi ye-flywheel

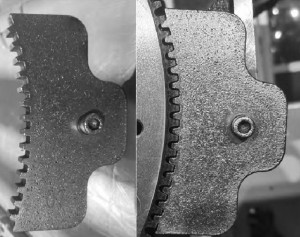

Ukujonga isixhobo sozipho kwisiza, kwafunyaniswa ukuba amazinyo esixhobo se-flywheel claw anxitywe kakhulu, kwaye amazinyo awakwazanga ukubandakanya igiya leringi ye-flywheel. Ngethuba lenkqubo yokuqiniswa kwezixhobo, i-flywheel iyagubha, ibangela ukuba umkhono ulungelelaniswe kakubi kunye nebholiti. Ngethuba lenkqubo yokuqinisa, i-sleeve igxuma ngaphandle kwe-bolt, okanye i-idly ijikeleze phezu kwendawo yebholiti, okubangelwa ukuqiniswa okungafanelekanga.

Buyisela isixhobo esitsha sozipho lwe-flywheel, umhla wokusetyenziswa uphawulwe kwisixhobo sokwenza uzipho lwe-flywheel, kwaye isixhobo kufuneka sitshintshwe rhoqo emva kweenyanga ezi-3 ukuphepha ukungcangcazela kwe-flywheel ngexesha lenkqubo yokuqinisa ngenxa yokunxiba kwe-claw, okuya kubangela ukuba i-shaft engafanelekanga yenzeke.

2. Isisombululo sokukhulula i-bayonet ye-tray

Jonga iirekhodi ze-pallet rework kwisiza. I pallets injini reworked kaninzi zigxile 021 #/038 #/068 #/201 #. Emva koko iipaliti zahlolwa kwaye zafumanisa ukuba izikhonkwane zokulungisa i-pallet zikhululekile. Ngenxa yoko, i-sleeve ayihambelani ne-bolt, i-sleeve igxuma iphuma kwi-bolt ngexesha lenkqubo yokuqinisa, okanye i-idling ebusweni be-bolt ibangela ukuqiniswa okungavumelekanga. Ukuba i-bolts yokulungisa i-bayonet ye-pallet ikhululiwe, i-bayonet ayikwazi ukulungiswa ngokufanelekileyo. Kwibhloko yokulungisa i-pallet, sebenzisa iibholiti ezongeziweyo (ezangaphambili iibholiti ezimfutshane), kwaye usebenzise amantongomane achasene ne-reverse yokukhulula ukuze uwalungise ukuze ugweme i-bayonet ye-bayonet ebangelwa ukukhulula i-pallet bayonet fixing bolts. Akunakulungiswa ngokufanelekileyo, okubangelwa ukuxubha kwe-flywheel kunye nokungahambi kakuhle kwe-shaft ngexesha lenkqubo yokuqinisa, engafanelekanga.

3. Lungiselela indlela yokuthatha imifanekiso yekhamera yesixhobo

Eli nyathelo lelona candelo linzima kakhulu kwisicwangciso. Ngenxa yokuba akukho parameters ukubhekisela kuyo, kuyimfuneko ukuhlola nokulawula izixhobo. Isicwangciso esithile:

(1) Lungisa kwakhona ulungelelwaniso lwemvelaphi

(2) Yandisa inkqubo yeparamitha yembuyekezo yecamera yeziko leefoto, enjengomngxuma osembindini wefoto, seta ixabiso lembuyekezo kunye nesixa solungiso kulungelelwaniso lweziko, kwaye ulungise indawo yokucima umngxuma ophakathi.

(3) Lungisa ixabiso lembuyekezo yokuvezwa kweKhamera.

Idatha yalandelwa ngokuqhubekayo kwaye yaqokelelwa kwiinyanga ezi-3. Ngeli xesha, izinga elifanelekileyo le-double-mass flywheel bolt tightening liguquguquka, kwaye izilungiso ezifanelekileyo kunye nohlengahlengiso lwenziwa kwiiparamitha zokufota. Ekuqaleni kuka-Epreli, ixabiso lembuyekezo yokuvezwa liye lahlengahlengiswa ukusuka kuma-2 800 ukuya kuma-2 000, kwaye izinga lemfundo eliqiniswayo linyuke laya kutsho kuma-97.75%. , kukho ukungaphumeleli okungaphezulu emva kokusebenza kokulandelela, kwaye ke ixabiso lokuvezwa kwekhamera lihlengahlengiswa: ukusuka kwi-2 000 ukuya kwi-1 800, eyanda ukuya kwi-98.12%; ukwenzela ukudibanisa imilinganiselo, ngexesha lenkqubo yokulandelela, ixabiso lokuvezwa kwekhamera liphuculwe kwakhona: ukusuka kwi-1 800 yaba yi-1 000, kwaye isantya sokuphumelela sokugqibela ngo-Aprili sanda ukuya kwi-99.12%; izinga lokuphumelela eliqiniswayo ngoMeyi nangoJuni liye lalandelelwa ngokuqhubekayo ukuya ngaphaya kwama-99%.

4. Ukufuna

I i-lug nutsI-flywheel sisixhobo esona sixhobo sibalaseleyo sokungcangcazela sodwa kunye nesiphumo sokunciphisa ukungcangcazela kwimoto yangoku. Ukungcangcazela kwenjini yedizili kukhulu kunokwenjini yepetroli. Ukuze kuncitshiswe ukungcangcazela kwe-injini ye-diesel kunye nokuphucula ukuhamba kakuhle, iimoto ezininzi ze-diesel zaseYurophu ngoku zisebenzisa i-flywheels ezimbini, ukuze ubumnandi bemoto ye-diesel bufaniswe nobo bemoto ye-injini yepetroli [6]. E-China, i-FAW-Volkswagen's Bora transmission sedan inkqenkqeza phambili ekwamkeleni i-dual-mass flywheels. Imfuno yemarike yee-flywheels ezinobunzima obumbini iyaqhubeka nokukhula, kwaye iimfuno zokuqiniswa kwemigangatho yesiqinisekiso nazo ziya phezulu kwaye ziphezulu [7]. Eli nqaku lihlalutya iingxaki eziqhelekileyo ezikhokelela ekuqiniseni i-flywheel yobunzima obuphindwe kabini, ifumana oyena nobangela, iqulunqa iindlela zokusombulula ingxaki, kwaye isombulule ingxaki ngokusisiseko. Okwangoku, izixhobo ziqhuba kakuhle, kwaye izinga lokuphumelela lihlala lingaphezulu kwama-99%. Isisombululo sale ngxaki sinentsingiselo entle yokonga iindleko zabasebenzi kunye nokuphucula umgangatho womzi-mveliso.

Ixesha lokuposa: Sep-29-2022