1. Ubunzima kwiNkqubo yeNdibano yeValve Core

Kolu phononongo, emva kokufunxa amava oyilo lwezinye iinkqubo zokuhlanganisa ezizenzekela, inkqubo yokuhlanganisana ekhoyo yesemi-automatic yahlalutywa, kwaye inxalenye yomatshini yenkqubo yayiyilwe ngokupheleleyo ngokusekelwe kukulinganisaundoqo wevalvuinkqubo yokuhlanganisa. Kwisicwangciso soyilo lwenkqubo, sizama ukwenza ukuba ukusetyenzwa kwamacandelo oomatshini kube lula, ukunciphisa iindleko, ukwenza ukudityaniswa kwamalungu kube lula kwaye kube lula, kwaye senze inkqubo ibe nenqanaba elithile lokuvuleleka kunye nokwandiswa, ukuze kuphuculwe ukuthembeka nokusebenza kakuhle kwenkqubo. , kwaye ubeke isiseko esihle sokuphucula ukusebenza kweendleko zenkqubo .

Iivalveundoqoinkqubo yokuhlanganisa yahlulwe ubukhulu becala ibe ngamacandelo amathathu ngokwemiqathango yoyilo lwesakhiwo soomatshini, ezizezi: iinxalenye ezimbini zendibano kwikona ephezulu ngasekhohlo yebhentshi yokusebenzela, iinxalenye ezintathu zendibano kwikona esezantsi ekhohlo kunye neenxalenye ezisixhenxe zendibano kwicala lasekunene lendawo yokusebenza. Ubunzima bobugcisa bendibano yamacandelo amabini buxhomekeke kwindlela yokuqinisekisa ukuma kwesetyhula kwindandatho yokutywina. Ngethuba lenkqubo yokusika, iya kufakwa phantsi kwe-axial extrusion force ye-blade, ngoko kulula ukukhubaza. Okwesibini, ngexesha lenkqubo yokuhlanganisana, xa i-cored rod ifunyenwe kwi-tooling tooling component, kuyimfuneko ukuqonda ukukhangela kunye nokudibanisa phakathi kwamacandelo ahlukeneyo engundoqo yomnyango ngokusebenzisa i-vibration. Ngoko ke, icandelo ngalinye liwela kwindawo ehambelanayo ukuze libe likhonkco lendibano. Ubunzima benkqubo bulele. Ezi ngxaki zingasentla zezona zizathu zokunyuka kwezinga lemveliso enesiphene kwindibano ye-valve core kweli nqanaba. Ngokusekelwe koku, eli phepha lilungiselela inkqubo yokudibanisa i-valve core, kwaye yongeza inkqubo yokuhlola umgangatho wokuphucula izinga lokufaneleka kwe-valve core assembly.

2. ISikimu seNdibano yeValve enoBuchule

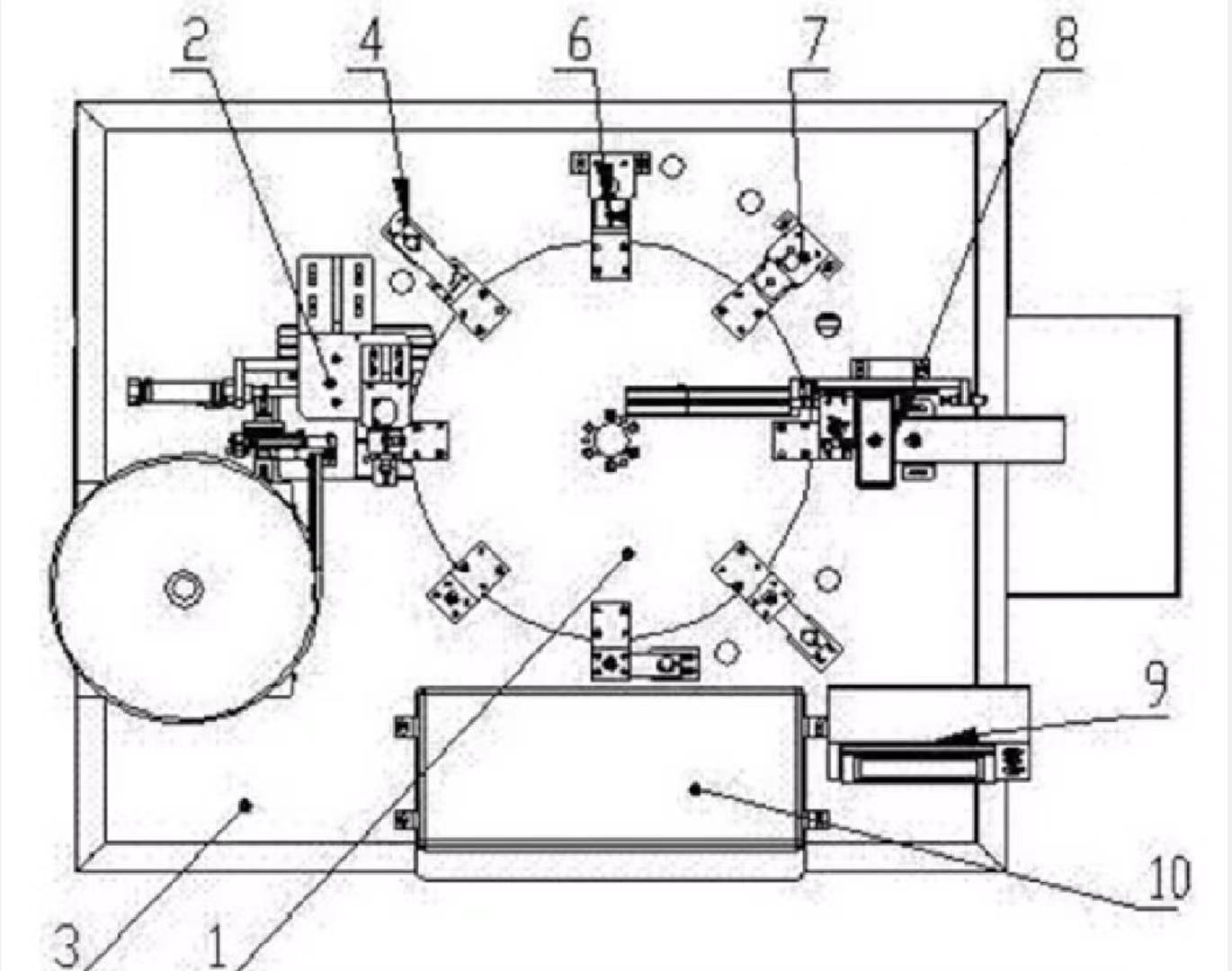

I-interface yokusebenza kunye ne-PLC yenze inxalenye yokulawula ingqiqo, kwaye inkqubo yokufumanisa kunye ne-PLC ineendlela ezimbini zokuhamba kolwazi ukuqokelela idatha yesimo senkqubo yendibano kunye nokukhupha isignali yokulawula. Njengenxalenye yesigqeba, inkqubo yokuqhuba ilawulwa ngokuthe ngqo yi-PLC inxalenye yemveliso. Ngaphandle kwenkqubo yokutya, efuna uncedo lwezandla, ezinye iinkqubo kule nkqubo ziye zaqonda indibano ekrelekrele. Ukusebenzisana okuhle komntu-kwikhompyuter kufezekiswa ngesikrini sokuchukumisa. Ukuqwalasela ukulungelelaniswa kokusebenza kuyilo lomatshini, ibhokisi yokubeka ingundoqo yomnyango isecaleni kwesikrini sokuchukumisa. Indlela yokubona, undoqo womnyango wokuvuthela icandelo elivuthela phezulu, icandelo lokubona ubude bevalve kunye nesixhobo sokuvala ngokulandelelanayo zicwangciswe ngokujikeleze icandelo lesixhobo se-turntable, ukuqonda uyilo lwemveliso yomgca wendibano yendibano engundoqo yocango. Inkqubo yokufumanisa ngokuyinhloko igqibezela ukufumanisa intonga engundoqo, ukukhangela ukuphakama kofakelo, ukuhlolwa komgangatho, njl., Engaqapheli nje ukuzenzekelayo kokukhethwa kwezinto kunye ne-valve core lock, kodwa iqinisekisa ukuzinza kunye nokusebenza okuphezulu kwenkqubo yokuhlanganisa. Ukwakhiwa kweyunithi nganye yenkqubo kuboniswe kuMfanekiso 1.

Njengoko kuboniswe kumzobo ongezantsi, i-turntable iyikhonkco ephakathi kwenkqubo yonke, kwaye indibano ye-valve core igqitywe ngokuqhutywa kwe-turntable. Xa indlela yesibini yokufumanisa ibona icandelo eliza kuhlanganiswa, lithumela isignali kwinkqubo yokulawula, kwaye inkqubo yokulawula ilungelelanisa umsebenzi weyunithi nganye yenkqubo. Okokuqala, idiski engcangcazelayo ishukumisa undoqo wocango kwaye iyitshixe kumlomo wevalve yokungena. Indlela yokuqala yokufumanisa iya kukhusela ngokuthe ngqo i-valve cores engazange ifakwe ngempumelelo njengezinto ezimbi. Icandelo lesi-6 lifumanisa ukuba i-ventilation ye-valve core ifanelekile, kwaye icandelo lesi-7 lifumanisa ukuba ukuphakama kofakelo lwe-valve core kuhambelana nomgangatho. Kuphela ziimveliso ezifanelekileyo kula makhonkco mathathu angasentla ziya kufakwa kwibhokisi yemveliso elungileyo, kungenjalo ziya kuphathwa njengemveliso eneziphene.

Indibano enengqondo yeundoqo wevalvububunzima bobugcisa boyilo lwenkqubo. Kulo yilo, uyilo lwe-cylinder ezintathu luyamkelwa. I-cylinder yesilayidi ilawula ukukhutshwa ukuze kuqinisekiswe ukungaqhelekanga kokukhutshwa; isilinda sesibini siqinisekisa ukuba intonga yokutshixa ilungelelaniswe nomngxuma wokukhupha, kwaye emva koko isebenzisane nesilayidi sesilayidi ukugqiba undoqo wevalve engena kwintonga yokutshixa, kwaye ke I-cylinder yesibini iyaqhubeka ukutyhala yonke indlela yokutshixa ukuze ihambe, kwaye umbhobho wokufunxa uya kufunxa ivalve xa ifika ezantsi kwesixhobo. Okokugqibela, emva kokuba isilinda sesithathu sityhala indlela yokutshixa endaweni, i-servo motor ithumela undoqo wevalve kumlomo wevalvu yokungena ukuze igqibezele ukudityaniswa kondoqo wevalve. Le nkqubo iqinisekisa ukuchaneka kunye nokukodwa kwezikhundla zentshukumo zelongitudinal kunye necala, kwaye ibonelela ngesisombululo esihle kubunzima bobugcisa bendibano engundoqo yomnyango..

3. Uyilo lwaMalungu aPhambili kwiNkqubo yeNdibano yeValve Core

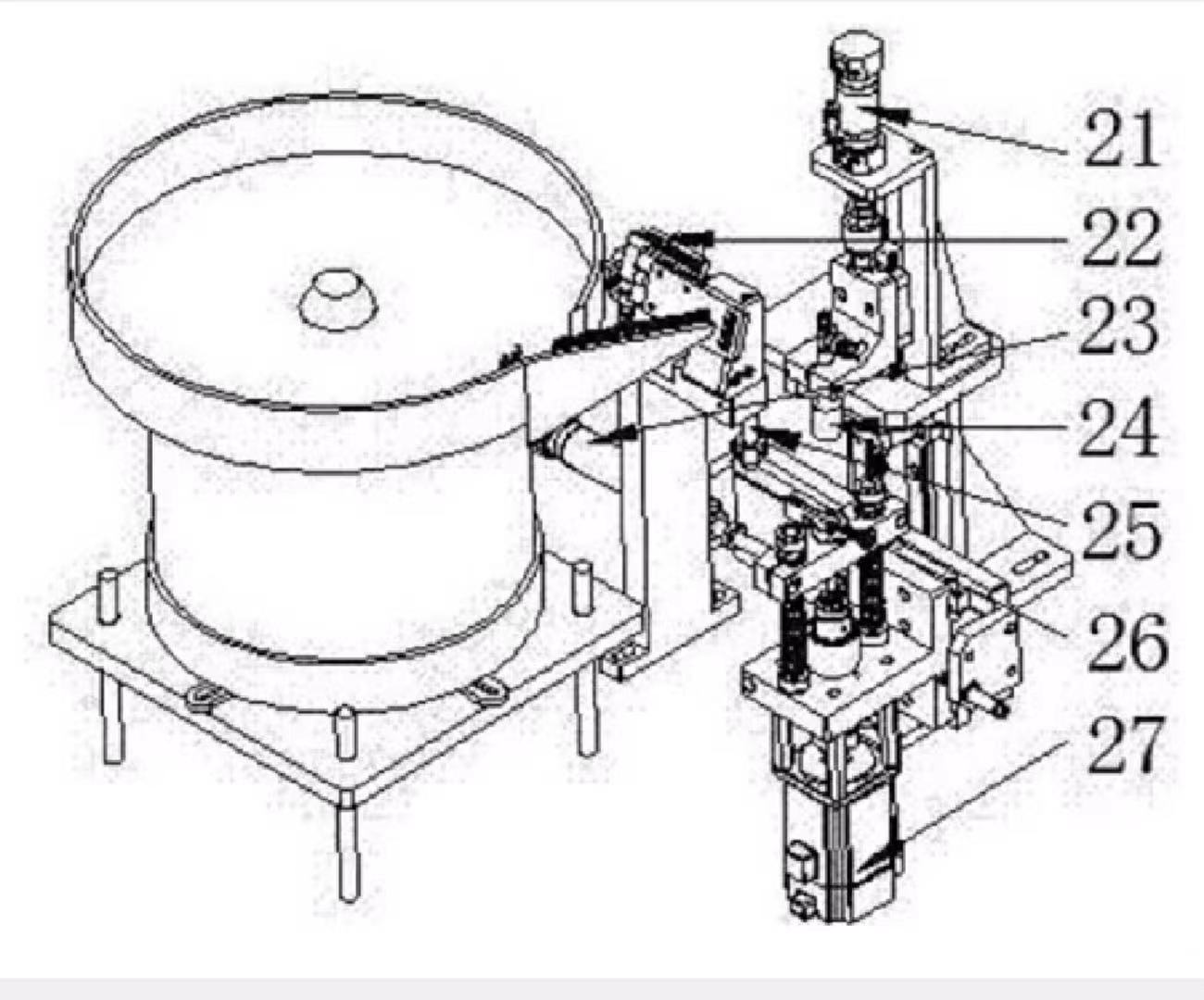

Njengenkqubo engundoqo yokufakela iundoqo wevalvukwivalve, ukutshixa i-valve core kuneemfuno eziphezulu kakhulu ekuchanekeni kwendawo yokuhamba ye-valve core, ngoko ke idinga ukulungelelaniswa kweendlela ze-longitudinal kunye ne-lateral ukuze igqibezele. Kuyilo lwale nxalenye, ibolile ibe yinto enye, isenzo sokukhupha i-valve core, isenzo sokutshixa i-lever yokutshixa kunye nesenzo sokulayisha i-valve core kwi-valve nozzle. Ubume bayo bomatshini buboniswe kuMfanekiso 2. Njengoko kunokubonwa kuMzobo 2, ukwakheka komatshini wendibano ye-valve core ihlukaniswe ngamacandelo amathathu. La malungu mathathu asebenza ngolungelelwaniso ngaphandle kokuchaphazela omnye nomnye. Xa isenzo esizimeleyo sigqityiwe, isilinda sityhala indlela yokufudukela kwindawo yokuhlanganisa elandelayo.

Ukuze kuqinisekiswe ukuchaneka kwendawo ehambayo, uyilo olubanzi lolawulo lombane kunye nomda womatshini wamkelwa ukulawula impazamo ngaphakathi kwe-1.4mm. Umbindi wevalve kunye nombindi womlomo wevalve zi-coaxial, ukuze i-servo motor ityhale undoqo wevalve kumlomo wevalve kakuhle, kungenjalo iya kubangela umonakalo kwiindawo. Ukuma kwesakhiwo soomatshini okanye ii-pulses ezingaqhelekanga zemiqondiso yombane kunokubangela ukuphambuka okuncinci kumsebenzi wendibano. Ngenxa yoko, emva kokuba i-valve core ihlanganiswe, ukusebenza kwe-ventilation ayikho kumgangatho, kwaye ukuphakama kwendibano akufanelekile, okukhokelela ekungaphumeleli kwemveliso. Lo mba uqwalaselwe ngokupheleleyo kuyilo lwenkqubo, ukufumanisa ukuvuthuza komoya kunye nokuchongwa kobude kusetyenziswa ukuhlenga iimveliso ezimbi.

Ixesha lokuposa: Sep-09-2022