1. Ngokufutshane

Intambo yangaphakathi esetyenziswe ngamaza e-longitudinal kwaye ekhethiweyo ukuba isetyenziswe ilungiswe nguiibholiti eziqhelekileyokunye neebholiti zokuzitshixa, ezilinganiswe ngamaqhinga ahlukeneyo okuqinisa, kwaye umahluko phakathi kweebholiti ze-anchor kunye ne-self-locking calibration i-anchoring characteristic curves ihlalutywa. Isiphumo: Indlela yokulinganisa ibholiti kunye nebholithi iya kufumana iimpawu zokulinganisa ezahlukeneyo, isikali sexesha lokutshixa lekhonkco lenza ukuzilinganisa ngokuzimeleyo kunye nexesha lokuzilinganisa lokuzilinganisa likhokelela kwiithagethi ezahlukeneyo. Ngenxa yegophe lentshukumo eqhelekileyo, iimpawu ezifunyenweyo ezahlukeneyo ziya kuhamba ngasekunene.

2. Ifilosofi yoVavanyo

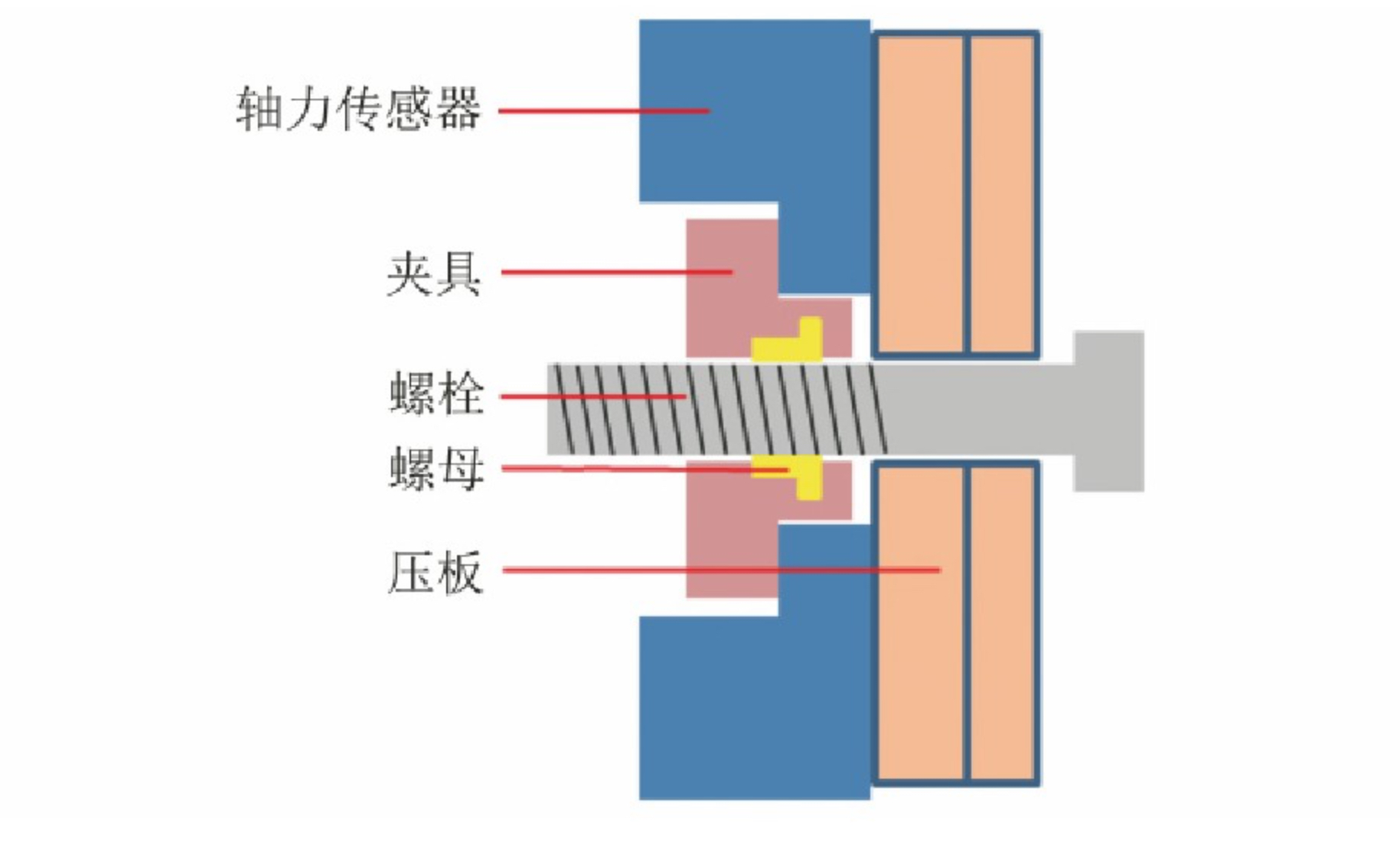

Okwangoku, indlela ye-ultrasonic isetyenziswa ngokubanzi kwiuvavanyo lwebholiti ye-axial forceindawo yokuqinisa i-subsystem yemoto, oko kukuthi, i-curve yeempawu zobudlelwane (i-bolt calibration curve) phakathi kwe-bolt axial force kunye nokwahlukana kwexesha lesandi se-ultrasonic ifunyenwe kwangaphambili, kwaye uvavanyo olulandelayo lwenxalenye yenkqubo engaphantsi iyenziwa. I-axial force ye-bolt ekuxhumaneni kokuqinisa inokufumaneka ngokulinganisa i-ultrasonically umehluko wexesha lesandi kunye nokubhekisela kwi-curve calibration. Ngoko ke, ukufumana ijika elichanekileyo lokulinganisa kubaluleke kakhulu ukuchaneka kwe-bolt axial force measurement result in the real part subsystem. Okwangoku, iindlela zovavanyo lwe-ultrasonic ikakhulu zibandakanya indlela yamaza amaza enye (okt indlela yamaza obude) kunye nendlela yamaza enqamlezayo.

Kwinkqubo yokulinganisa i-bolt, kukho izinto ezininzi ezichaphazela iziphumo zokulinganisa, ezifana nobude be-clamping, ubushushu, isantya somatshini wokuqinisa, i-fixture tooling, njl. Iibholiti zilinganiswe kwibhentshi yokuvavanya i-bolt, efuna ukuveliswa kwezixhobo ezixhasayo kwi-axial force sensor, eyiplate yoxinzelelo kunye nokulungiswa komngxuma ongaphakathi. Umsebenzi womngxunya wangaphakathi odityanisiweyo kukubuyisela amandongomane aqhelekileyo. Uyilo oluchasene ne-Anti-loose ludla ngokusetyenziswa kwiindawo zokuqhagamshelwa ngokukhawuleza kunye nokhuseleko oluphezulu lwe-chassis yemoto ukuqinisekisa ukuthembeka kokuqina kwayo. Enye yeendlela ezichasayo ezamkelweyo ngoku yi-nati yokuzivalela, oko kukuthi, i-torque esebenzayo yokutshixa i-nut.

Umbhali wamkela indlela yamaza emide kwaye usebenzisa umsonto owenziweyo wangaphakathi ukuze ukhethe i-nut eqhelekileyo kunye ne-nati yokuzivalela ukulinganisa ibholithi. Ngeendlela ezahlukeneyo zokuqiniswa kunye neendlela zokulinganisa, umahluko phakathi kwentongomane eqhelekileyo kunye ne-self-locking nut ukulinganisa i-bolt curve iyafundwa. Uvavanyo lwamandla e-Axial ye-automotive subsystem fasteners yenza iingcebiso ezithile.

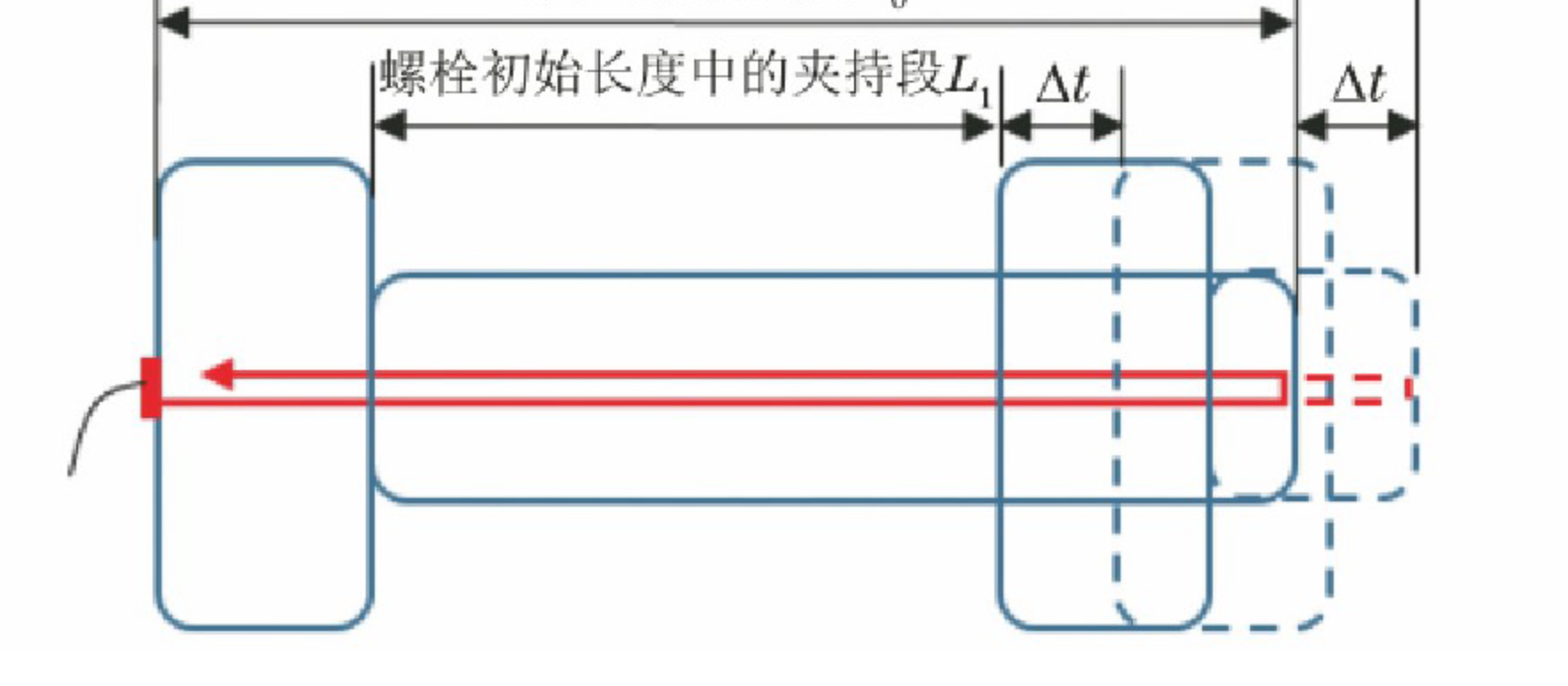

Ukuvavanya amandla e-axial ye-bolts ngeteknoloji ye-ultrasonic yindlela yokuvavanya ngokungathanga ngqo. Ngokomgaqo we-sonoelasticity, isantya sokusasazwa kwesandi kwizinto eziqinileyo zihambelana noxinzelelo, ngoko ke amaza e-ultrasonic angasetyenziselwa ukufumana i-axial force of bolts [5-8]. I-bolt iya kuzolula ngokwayo ngexesha lenkqubo yokuqinisa, kwaye kwangaxeshanye ivelise uxinzelelo lwe-axial tensile. I-pulse ye-ultrasonic iya kudluliselwa ukusuka kwintloko yebholi ukuya kumsila. Ngenxa yotshintsho olukhawulezileyo kubuninzi bendawo ephakathi, iya kubuya ecaleni kwendlela yokuqala, kwaye umphezulu webholithi uya kufumana umqondiso ngeceramic piezoelectric. Umahluko wexesha Δt. Umzobo we-schematic wovavanyo lwe-ultrasonic uboniswe kuMfanekiso 1. Ukwahlukana kwexesha kuhambelana nokunyuka.

Ukuvavanya amandla e-axial ye-bolts ngeteknoloji ye-ultrasonic yindlela yokuvavanya ngokungathanga ngqo. Ngokomgaqo we-sonoelasticity, isantya sokusasazwa kwesandi kwizinto eziqinileyo zihambelana noxinzelelo, ngoko ke amaza e-ultrasonic angasetyenziselwa ukufumana.amandla e-axial yeebholithi. I-bolt iya kuzolula ngokwayo ngexesha lenkqubo yokuqinisa, kwaye kwangaxeshanye ivelise uxinzelelo lwe-axial tensile. I-pulse ye-ultrasonic iya kudluliselwa ukusuka kwintloko yebholi ukuya kumsila. Ngenxa yotshintsho olukhawulezileyo kubuninzi bendawo ephakathi, iya kubuya ecaleni kwendlela yokuqala, kwaye umphezulu webholithi uya kufumana umqondiso ngeceramic piezoelectric. Umahluko wexesha Δt. Umzobo we-schematic wovavanyo lwe-ultrasonic uboniswe kuMfanekiso 1. Ukwahlukana kwexesha kuhambelana nokunyuka.

M12 mm × 1.75 mm × 100 mm kwaye ke ukucaciswa kweebholiti, sebenzisa iibholiti eziqhelekileyo ukulungisa iibholithi ezi-5, okokuqala sebenzisa uvavanyo lokuzibophelela ngeankile ngeendlela ezahlukeneyo zokuncamathisela i-solder yokulinganisa, ipleyiti yokwenziwa spiral ukuba ibhontile iflange kufanelekile kwaye ucinezele Xa uskena i-wave yokuqala (oko kukuthi, i-N0 0 0), urekhoda i-wave yokuqala (oko kukuthi, i-N0 0 0), urekhoda i-l 0 0 °, kwaye urekhode i-N0 ° ye-0 0. ngesixhobo esinye (esibizwa ngohlobo lwe-I indlela), kwaye enye kukuskena i-wave yokuqala kwaye uyijije kwisayizi ekujoliswe kuyo ngompu wokuqinisa (okuthiwa luhlobo lwendlela ye-I). Kwindlela yohlobo lwesibini), kuya kubakho uhlobo oluthile kule nkqubo (njengoko kubonisiwe kwi-Figure 4) i-5 yi-bolt eqhelekileyo kunye nendlela yokuzivalela I-curve emva kokulinganisa ngokohlobo lwe-I indlela ye-Figure 6 luhlobo lokuzivalela. Umzobo 6 yiklasi yokuzivalela. Iklasi I kunye neClass II ijika. Indlela yokusetyenziswa ingaba, sebenzisa i-curve yesiko leklasi ye-anchor eqhelekileyo, ngokufanayo (zonke zidlula kwimvelaphi kunye nesantya secandelo elifanayo kunye nenani lamanqaku); tshixa uhlobo lwesalathiso sohlobo lwe-anchor (uhlobo I kunye ne-anchor mark, i-slope ye-interval umahluko kunye nenani lamanqaku); fumana ezifanayo)

Uvavanyo lwe-3 kukuseta ulungelelwaniso lwe-Y3 lwe-Graph Setup kwi-software yesixhobo sokufumana idatha njengolungelelwaniso lobushushu (usebenzisa i-sensor yangaphandle yobushushu), setha umgama we-idling we-bolt ukuya kwi-60 mm yokulinganisa, kwaye urekhode i-torque / i-axial force / ubushushu kunye ne-curve ye-angle. Njengoko kuboniswe kwi-Figure 8, kunokubonwa ukuba kunye ne-screwing eqhubekayo ye-bolt, iqondo lokushisa likhuphuka ngokuqhubekayo, kwaye ukunyuka kweqondo lokushisa kunokuthathwa njengomgca. Iisampulu ezine zebholiti zikhethelwe ukulinganisa ngamantongomane okuzivalela. Umzobo we-9 ubonisa iigophe zokulinganisa iibholiti ezine. Kuyabonakala ukuba iigophe ezine zonke ziguqulelwe ngasekunene, kodwa iqondo lokuguqulela lihlukile. Itheyibhile yesi-2 irekhoda umgama wokuba ijika lokulinganisa litshintshela ngasekunene kunye nokwanda kweqondo lokushisa ngexesha lenkqubo yokuqinisa. Ingabonwa ukuba iqondo lokutshintshela kwigophe lokulinganisa ukuya ngasekunene ngokusisiseko lilingana nokunyuka kobushushu.

3. Isiphelo kunye neNgxoxo

I-bolt ixhomekeke kwisenzo esidibeneyo soxinzelelo lwe-axial kunye noxinzelelo lwe-torsional ngexesha lokuqina, kwaye umphumo wesiphumo sesibini ekugqibeleni ubangela ukuba i-bolt ivelise. Kukulungelelaniswa kwebholithi, kuphela amandla e-axial ebholithi abonakaliswe kwigophe lokulinganisa ukubonelela ngamandla okuqinisayo wenkqubo engaphantsi yokuqina. Inokubonwa kwiziphumo zovavanyo kwi-Figure 5 ukuba, nangona i-nati yokuzivalela, ukuba ubude bokuqala burekhodwa emva kokuba i-bolt ijikelezwe ngesandla ukuya kwindawo apho ilungele ukulingana nomgangatho wokuthwala ipleyiti yoxinzelelo, iziphumo ze-curve zokulinganisa zihambelana ngokupheleleyo nezo ze-nut eqhelekileyo. Oku kubonisa ukuba kulo mbuso, impembelelo ye-torque yokuzivalela ye-self-locking nut ayinanto.

Ukuba i-bolt igxininiswe ngokuthe ngqo kwi-self-locking nut kunye nompu wombane, i-curve iya kutshintshela ngasekunene xa iyonke, njengoko kuboniswe kuMzobo 6. Oku kubonisa ukuba i-torque yokuzivalela ichaphazela ukuhluka kwexesha le-acoustic kwi-curve yokulinganisa. Qaphela icandelo lokuqala lejika elitshintshelwe ngasekunene, libonisa ukuba amandla e-axial ayikaveliswa phantsi kwemeko yokuba i-bolt inomlinganiselo othile wokwandisa, okanye i-axial force incinci kakhulu, ilingana nokuba i-bolt ayizange icinezelwe ngokuchasene ne-axial force sensor. Ukolula, ngokucacileyo ukolulwa kwebholiti ngeli xesha lubude obungeyonyani, asilulo lokwenyani. Isizathu sokwandisa ubuxoki kukuba ukushisa okwenziwa yi-torque yokuzivalela ngexesha lenkqubo yokuqinisa umoya kuchaphazela ukusasazeka kwamaza e-ultrasonic, abonakaliswe kwi-curve. Ibonisa ukuba i-bolt iye yandiswa, ibonisa ukuba ubushushu bunefuthe kwi-ultrasonic wave. KuMzobo we-6, i-nut yokuzivalela isetyenziselwa ukulinganisa, kodwa isizathu sokuba ijika lokulinganisa lingatshintshi ukuya ngasekunene kukuba nangona kukho ukungqubuzana xa u-screwing kwi-self-locking nut, ubushushu buveliswa, kodwa ukushisa kufakwe ekurekhodweni kobude bokuqala bebholiti. Icociwe, kwaye ixesha lokulinganisa ibholiti lifutshane kakhulu (lidla ngokuba ngaphantsi kwe-5s), ngoko ke isiphumo sobushushu asibonakali kwigophe lophawu lokulinganisa.

Inokubonwa kolu hlalutyo lungentla ukuba i-thread friction kwi-screwing yomoya ibangela ukunyuka kweqondo lokushisa kwe-bolt, okunciphisa i-ultrasonic wave velocity, ebonakaliswa njengenguqu ehambelanayo ye-curve calibration ukuya ngasekunene. I-Torque, ezo zombini zihambelana nobushushu obuveliswa yintambo yentambo, njengoko kuboniswe kuMzobo 10. KwiThebhile 2, ubukhulu bokutshintsha okufanelekileyo kwe-curve yokulinganisa kunye nokunyuka kweqondo lokushisa kwi-bolt ngexesha lenkqubo yonke yokuqinisa kubalwa. Ingabonwa ukuba ubukhulu benguqu echanekileyo ye-curve yokulinganisa ihambelana neqondo lokunyuka kweqondo lokushisa, kwaye inobudlelwane obulinganayo obulinganayo. Umlinganiselo umalunga ne-10.1. Ukucinga ukuba izinga lokushisa linyuka nge-10 ° C, ukuhluka kwexesha le-acoustic kwanda nge-101ns, ehambelana ne-axial force ye-24.4kN kwi-curve yokulinganisa i-bolt ye-M12. Ukusuka kumbono womzimba, kuchazwa ukuba ukunyuka kweqondo lokushisa kuya kubangela ukuba ipropathi ye-resonant ye-bolt itshintshe, ukwenzela ukuba i-ultrasonic wave isantya ngokusebenzisa i-bolt medium utshintsho kwaye emva koko ichaphazela ixesha lokusabalalisa i-ultrasonic.

4. Ingcebiso

Xa usebenzisa i-nut eqhelekileyo kunyeukuzitshixa nutukulinganisa igophe lophawu lwebholithi, iigophe zeempawu ezahlukeneyo zokulinganisa ziya kufumaneka ngenxa yeendlela ezahlukeneyo. I-torque eqinisiweyo ye-nati yokuzitshixa inyusa ubushushu be-bolt, okwandisa ukuhluka kwexesha le-ultrasonic, kunye ne-curve ye-calibration efunyenweyo iya kutshintshela ngasekunene ngokufanayo.

Ngexesha lovavanyo lwebhubhoratri, impembelelo yeqondo lokushisa kwi-ultrasonic wave kufuneka isuswe kangangoko kunokwenzeka, okanye indlela yokulinganisa efanayo kufuneka yamkelwe kwizigaba ezimbini zokulinganisa i-bolt kunye novavanyo lwe-axial force.

Ixesha lokuposa: Oct-19-2022